Short overview

A hierarchical query (or hierarchical queries) is a special type of query in oracle used to retrieve and process parent-child relationships within a data set. The key clauses used to build such a query include;

- start with: defines the root of the cycle

- connect by: specifies the relationship between child and parent

- prior: A mandatory operator that tells Oracle which expression refers to the parent row

- level: a pseudocolumn that automatically assigns a number representing the depth in the tree

- nocycle: revents infinite loops if the data accidentally contains a circular reference

More details about these cluases can be found here : hierarchical queries in oracle

There also exists recursive common table expressions which can be used to solve hierarchical queries

I was once given a requirement that required me to employ hierarchical queries to resolve… with a twist

This blog post serves to describe that problem(not the exact one but the same idea) and the resolutions I took

THE DATA

In order to describe the problem, let’s create a table and insert some data.

CREATE TABLE bom_table

(

pk_seq NUMBER

,root_parent VARCHAR2(100 CHAR)

,end_item VARCHAR2(100 CHAR)

,parent_part VARCHAR2(100 CHAR)

,part_number VARCHAR2(100 CHAR)

,bom_level NUMBER

,part_lead_time NUMBER

,CONSTRAINT bom_table_pk PRIMARY KEY (pk_seq)

);

Insert into BOM_TABLE (PK_SEQ,ROOT_PARENT,END_ITEM,PARENT_PART,PART_NUMBER,BOM_LEVEL,PART_LEAD_TIME) values (1,'CAR','BODY','CAR','BODY',1,3);

Insert into BOM_TABLE (PK_SEQ,ROOT_PARENT,END_ITEM,PARENT_PART,PART_NUMBER,BOM_LEVEL,PART_LEAD_TIME) values (2,'CAR','BODY','BODY','DOOR',2,2);

Insert into BOM_TABLE (PK_SEQ,ROOT_PARENT,END_ITEM,PARENT_PART,PART_NUMBER,BOM_LEVEL,PART_LEAD_TIME) values (3,'CAR','BODY','DOOR','WINDOW',3,1);

Insert into BOM_TABLE (PK_SEQ,ROOT_PARENT,END_ITEM,PARENT_PART,PART_NUMBER,BOM_LEVEL,PART_LEAD_TIME) values (4,'CAR','BODY','WINDOW','BOLT',4,1);

Insert into BOM_TABLE (PK_SEQ,ROOT_PARENT,END_ITEM,PARENT_PART,PART_NUMBER,BOM_LEVEL,PART_LEAD_TIME) values (5,'CAR','ENGINE','CAR','ENGINE',1,4);

Insert into BOM_TABLE (PK_SEQ,ROOT_PARENT,END_ITEM,PARENT_PART,PART_NUMBER,BOM_LEVEL,PART_LEAD_TIME) values (6,'CAR','ENGINE','ENGINE','CYLINDER',2,2);

Insert into BOM_TABLE (PK_SEQ,ROOT_PARENT,END_ITEM,PARENT_PART,PART_NUMBER,BOM_LEVEL,PART_LEAD_TIME) values (7,'CAR','ENGINE','CYLINDER','PISTON',3,3);

Insert into BOM_TABLE (PK_SEQ,ROOT_PARENT,END_ITEM,PARENT_PART,PART_NUMBER,BOM_LEVEL,PART_LEAD_TIME) values (8,'CAR','ENGINE','PISTON','SCREW',4,1);

Insert into BOM_TABLE (PK_SEQ,ROOT_PARENT,END_ITEM,PARENT_PART,PART_NUMBER,BOM_LEVEL,PART_LEAD_TIME) values (9,'CAR','ENGINE','CYLINDER','VALVE',3,4);

Insert into BOM_TABLE (PK_SEQ,ROOT_PARENT,END_ITEM,PARENT_PART,PART_NUMBER,BOM_LEVEL,PART_LEAD_TIME) values (10,'CAR','ENGINE','VALVE','SPRING',4,1);

Insert into BOM_TABLE (PK_SEQ,ROOT_PARENT,END_ITEM,PARENT_PART,PART_NUMBER,BOM_LEVEL,PART_LEAD_TIME) values (11,'CAR','FRAME','CAR','FRAME',1,2);

Insert into BOM_TABLE (PK_SEQ,ROOT_PARENT,END_ITEM,PARENT_PART,PART_NUMBER,BOM_LEVEL,PART_LEAD_TIME) values (12,'CAR','FRAME','FRAME','SUPPORT',2,2);

Insert into BOM_TABLE (PK_SEQ,ROOT_PARENT,END_ITEM,PARENT_PART,PART_NUMBER,BOM_LEVEL,PART_LEAD_TIME) values (13,'BIKE','FRAME','BIKE','FRAME',1,3);

Insert into BOM_TABLE (PK_SEQ,ROOT_PARENT,END_ITEM,PARENT_PART,PART_NUMBER,BOM_LEVEL,PART_LEAD_TIME) values (14,'BIKE','FRAME','FRAME','PEDAL',2,2);

Insert into BOM_TABLE (PK_SEQ,ROOT_PARENT,END_ITEM,PARENT_PART,PART_NUMBER,BOM_LEVEL,PART_LEAD_TIME) values (15,'BIKE','FRAME','PEDAL','BOLT',3,1);

Insert into BOM_TABLE (PK_SEQ,ROOT_PARENT,END_ITEM,PARENT_PART,PART_NUMBER,BOM_LEVEL,PART_LEAD_TIME) values (16,'BIKE','HANDLE','BIKE','HANDLE',1,2);

Insert into BOM_TABLE (PK_SEQ,ROOT_PARENT,END_ITEM,PARENT_PART,PART_NUMBER,BOM_LEVEL,PART_LEAD_TIME) values (17,'BIKE','HANDLE','HANDLE','GEAR',2,3);

SQL> select * from

2* bom_table;

PK_SEQ ROOT_PARENT END_ITEM PARENT_PART PART_NUMBER BOM_LEVEL PART_LEAD_TIME

_________ ______________ ___________ ______________ ______________ ____________ _________________

1 CAR BODY CAR BODY 1 3

2 CAR BODY BODY DOOR 2 2

3 CAR BODY DOOR WINDOW 3 1

4 CAR BODY WINDOW BOLT 4 1

5 CAR ENGINE CAR ENGINE 1 4

6 CAR ENGINE ENGINE CYLINDER 2 2

7 CAR ENGINE CYLINDER PISTON 3 3

8 CAR ENGINE PISTON SCREW 4 1

9 CAR ENGINE CYLINDER VALVE 3 4

10 CAR ENGINE VALVE SPRING 4 1

11 CAR FRAME CAR FRAME 1 2

12 CAR FRAME FRAME SUPPORT 2 2

13 BIKE FRAME BIKE FRAME 1 3

14 BIKE FRAME FRAME PEDAL 2 2

15 BIKE FRAME PEDAL BOLT 3 1

16 BIKE HANDLE BIKE HANDLE 1 2

17 BIKE HANDLE HANDLE GEAR 2 3

17 rows selected.The table above is named bom_table, standing for “Bill of Material” table which is a comprehensive list of raw materials, sub-assemblies, sub-components, parts and the quantities needed to manufacture a product. (for simplicity of the above example, no quantities have been included).

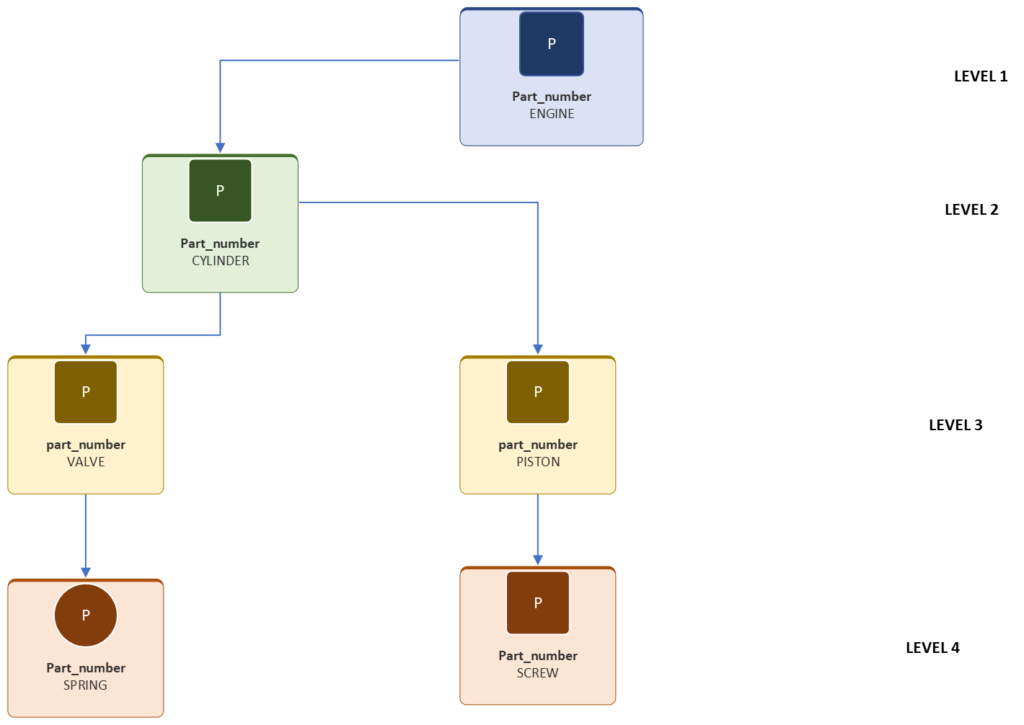

examination of the data shows a table storing information about the component parts needed to build a “car” and a “bike”. The oversimplified example shows that to build a car, a body , engine and frame is required. an engine needs a cylinder and a piston, pistons require screws and cylinders require valves and finally valves require springs. If you pick any end_item(in my example : engine, body and frame of a car) you can go down the tree until you get to the bottom. see below illustration for clarity:

THE PROBLEM

For the above sample data set, consider the below requirement

“Can we please get the total reorder lead time for all end items needed to build a part?” . This was the requirement that came in that took quite some figuring out. It needs some explaining however: in the sample data above, the lead time represents the time it will take to build a particular part. the total reorder lead time represents the longest time it will take to build a part, considering the longest lead time of all sub parts… simple right! let me explain further, for example:

SQL> SELECT part_number, parent_part, root_parent|| sys_connect_by_path(part_number, ' <- ') part_buildup, bom_level

2 FROM bom_table

3 WHERE root_parent = 'CAR'

4 START WITH bom_level = 1

5 CONNECT by prior part_number = parent_part

6 ORDER BY LEVEL

7* ;

PART_NUMBER PARENT_PART PART_BUILDUP BOM_LEVEL

-------------------- -------------------- ---------------------------------------------------------------------------------------------------- ----------

ENGINE CAR CAR <- ENGINE 1

FRAME CAR CAR <- FRAME 1

BODY CAR CAR <- BODY 1

DOOR BODY CAR <- BODY <- DOOR 2

SUPPORT FRAME CAR <- FRAME <- SUPPORT 2

CYLINDER ENGINE CAR <- ENGINE <- CYLINDER 2

SUPPORT FRAME CAR <- FRAME <- SUPPORT 2

PISTON CYLINDER CAR <- ENGINE <- CYLINDER <- PISTON 3

VALVE CYLINDER CAR <- ENGINE <- CYLINDER <- VALVE 3

WINDOW DOOR CAR <- BODY <- DOOR <- WINDOW 3

SCREW PISTON CAR <- ENGINE <- CYLINDER <- PISTON <- SCREW 4

SPRING VALVE CAR <- ENGINE <- CYLINDER <- VALVE <- SPRING 4

BOLT WINDOW CAR <- BODY <- DOOR <- WINDOW <- BOLT 4

taking a closer look at our data above you can see how the parts roll into their parents which roll into their parents and so on and so forth until the root parent (in this case a car)

if we take an engine as a set case ,

1 select END_ITEM,parent_part, part_number, bom_level, Part_lead_time

2 from bom_table

3 where root_parent = 'CAR'

4 and end_item = 'ENGINE'

5* ORDER BY BOM_LEVEL ASC

SQL> /

END_ITEM PARENT_PART PART_NUMBER BOM_LEVEL PART_LEAD_TIME

-------------------- -------------------- -------------------- ---------- --------------

ENGINE CAR ENGINE 1 4

ENGINE ENGINE CYLINDER 2 2

ENGINE CYLINDER PISTON 3 3

ENGINE CYLINDER VALVE 3 4

ENGINE PISTON SCREW 4 1

ENGINE VALVE SPRING 4 1

it takes 1 day to build a spring and one day to build a screw, and considering that both can be built consecutively then at level 4 of an engine the longest lead time is 1. at level 3 which is the level above 4, it takes 4 days to build a valve and 3 days to build a piston, so the longest lead time is 4 which is the time it takes to build a valve, however a valve requires a spring which takes one day and thus the reorder lead time for a valve is 5. at level 2, the cylinder takes 2 days to build and requires a piston and a valve for which the longest reorder lead time between them is the valve at 5 days so 5+2 = 7 days the total reorder lead time for the cylinder. And finally the engine takes 4 days to build and thus the total reorder lead time for the end item the engine is 7+4 = 11 days. That is what the request above is asking of us programatically.

THE SOLUTION

Acknowledgement : I am convinced , (although I haven’t figured it out quite yet myself) that there could be a better way to arrive at this solution using plain old SQL unfortunately after a lot of back and forth trying multiple analytics like lag and lead, I resorted to using a PL/SQL function. So if you read this and perhaps have a better way of doing this in SQL I will be happy to hear from you in the comments.

As, the above paragraph explains, I resorted to a PL/SQL function to resolve the above requirement. the code looked like this :

FUNCTION get_reorder_lead_time (

p_part_number IN VARCHAR2,

p_root_parent IN VARCHAR2

) RETURN NUMBER IS

TYPE bom_rec IS RECORD (

part_number VARCHAR2(100),

parent_part VARCHAR2(100),

bom_level NUMBER,

part_lead_time NUMBER

);

TYPE bom_table_type IS TABLE OF bom_rec INDEX BY PLS_INTEGER;

bom_data bom_table_type;

TYPE child_map_type IS TABLE OF SYS.ODCIVARCHAR2LIST INDEX BY VARCHAR2(100);

child_map child_map_type;

TYPE time_map_type IS TABLE OF NUMBER INDEX BY VARCHAR2(100);

time_map time_map_type;

result_cache time_map_type;

v_idx INTEGER := 0;

FUNCTION calc_chain(p_part VARCHAR2) RETURN NUMBER IS

v_max_child_chain NUMBER := 0;

v_total NUMBER;

BEGIN

IF result_cache.EXISTS(p_part) THEN

RETURN result_cache(p_part);

END IF;

IF NOT child_map.EXISTS(p_part) THEN

result_cache(p_part) := NVL(time_map(p_part), 0);

RETURN result_cache(p_part);

END IF;

FOR i IN 1 .. child_map(p_part).COUNT LOOP

v_total := calc_chain(child_map(p_part)(i));

IF v_total > v_max_child_chain THEN

v_max_child_chain := v_total;

END IF;

END LOOP;

result_cache(p_part) := NVL(time_map(p_part), 0) + v_max_child_chain;

RETURN result_cache(p_part);

END;

BEGIN

FOR r IN (

SELECT part_number, parent_part, bom_level, NVL(part_lead_time, 0) AS part_lead_time

FROM bom_table

WHERE root_parent = p_root_parent

ORDER BY pk_seq

) LOOP

v_idx := v_idx + 1;

bom_data(v_idx).part_number := r.part_number;

bom_data(v_idx).parent_part := r.parent_part;

bom_data(v_idx).bom_level := r.bom_level;

bom_data(v_idx).part_lead_time := r.part_lead_time;

-- Store lead time

time_map(r.part_number) := r.part_lead_time;

-- Map child to parent

IF r.parent_part IS NOT NULL THEN

IF NOT child_map.EXISTS(r.parent_part) THEN

child_map(r.parent_part) := SYS.ODCIVARCHAR2LIST();

END IF;

child_map(r.parent_part).EXTEND;

child_map(r.parent_part)(child_map(r.parent_part).COUNT) := r.part_number;

END IF;

END LOOP;

IF NOT time_map.EXISTS(p_part_number) THEN

RETURN 0;

END IF;

RETURN calc_chain(p_part_number);

EXCEPTION

WHEN OTHERS THEN

RETURN 0;

END;

As you can see, not quite the easiest of functions to read, matter of fact it’s actually quite cryptic and has a lot of PL/SQL concepts employed which I will not go deep into explaining in this post, but at a high level the function accepts a part and it’s root parent as input arguments, generates a “tree” of subparents for that part, calculates the longest lead time at each hierarchy level, adds it to the specified part’s lead time and returns the “reorder lead time for that part”. (phew 😥)

In practice this is the output returned by using the function:

select parent_part, part_number, bom_level, Part_lead_time, get_reorder_lead_time(part_number, root_parent) longest_lead_time

from bom_table

where root_parent = 'CAR'

and end_item = 'ENGINE'

ORDER BY BOM_LEVEL ASC

/

PARENT_PART PART_NUMBER BOM_LEVEL PART_LEAD_TIME LONGEST_LEAD_TIME

-------------------- -------------------- ---------- -------------- -----------------

CAR ENGINE 1 4 11

ENGINE CYLINDER 2 2 7

CYLINDER PISTON 3 3 4

CYLINDER VALVE 3 4 5

PISTON SCREW 4 1 1

VALVE SPRING 4 1 1

As explained earlier, you can see that the function correctly computes the longest lead time for an engine based on it’s subcomponnents and that is 11 days. the reorder lead time for every subcomponnent at any level of the BOM can be computed as well. the below query displays the same information for every part needed to build a “car” based on the sample data as well as using sys_connect_by_path to show the “tree” if you may.

SELECT part_number, parent_part, root_parent|| sys_connect_by_path(part_number, ' <- ') part_buildup, bom_level, get_reorder_lead_time(part_number, root_parent) reorder_lead_time

2 FROM bom_table

3 WHERE root_parent = 'CAR'

4 START WITH bom_level = 1

5 CONNECT by prior part_number = parent_part

6 ORDER BY LEVEL

7* ;

PART_NUMBER PARENT_PART PART_BUILDUP BOM_LEVEL REORDER_LEAD_TIME

-------------------- -------------------- ---------------------------------------------------------------------------------------------------- ---------- -----------------

ENGINE CAR CAR <- ENGINE 1 11

FRAME CAR CAR <- FRAME 1 4

BODY CAR CAR <- BODY 1 7

DOOR BODY CAR <- BODY <- DOOR 2 4

SUPPORT FRAME CAR <- FRAME <- SUPPORT 2 2

CYLINDER ENGINE CAR <- ENGINE <- CYLINDER 2 7

SUPPORT FRAME CAR <- FRAME <- SUPPORT 2 2

PISTON CYLINDER CAR <- ENGINE <- CYLINDER <- PISTON 3 4

VALVE CYLINDER CAR <- ENGINE <- CYLINDER <- VALVE 3 5

WINDOW DOOR CAR <- BODY <- DOOR <- WINDOW 3 2

SCREW PISTON CAR <- ENGINE <- CYLINDER <- PISTON <- SCREW 4 1

SPRING VALVE CAR <- ENGINE <- CYLINDER <- VALVE <- SPRING 4 1

BOLT WINDOW CAR <- BODY <- DOOR <- WINDOW <- BOLT 4 1

And returning to the original request, displaying the lead time for all the “end_items” for a car:

1 select distinct end_item, get_reorder_lead_time(end_item, root_parent) longest_lead_time

2 from bom_table

3* where root_parent = 'CAR'

SQL> /

END_ITEM LONGEST_LEAD_TIME

-------------------- -----------------

FRAME 4

ENGINE 11

BODY 7This could also be done for Bikes in the sample data

1 SELECT part_number, parent_part, root_parent|| sys_connect_by_path(part_number, ' <- ') part_buildup, bom_level, get_reorder_lead_time(part_number, root_parent) reorder_lead_time

2 FROM bom_table

3 WHERE root_parent = 'BIKE'

4 START WITH bom_level = 1

5 CONNECT by prior part_number = parent_part

6* ORDER BY LEVEL

SQL> /

PART_NUMBER PARENT_PART PART_BUILDUP BOM_LEVEL REORDER_LEAD_TIME

-------------------- -------------------- -------------------------------------------------------------------------------- ---------- -----------------

FRAME BIKE BIKE <- FRAME 1 6

HANDLE BIKE BIKE <- HANDLE 1 5

GEAR HANDLE BIKE <- HANDLE <- GEAR 2 3

PEDAL FRAME BIKE <- FRAME <- PEDAL 2 3

PEDAL FRAME BIKE <- FRAME <- PEDAL 2 3

BOLT PEDAL BIKE <- FRAME <- PEDAL <- BOLT 3 1

BOLT PEDAL BIKE <- FRAME <- PEDAL <- BOLT 3 1

1 select distinct end_item, get_reorder_lead_time(end_item, root_parent) longest_lead_time

2 from bom_table

3* where root_parent = 'BIKE'

SQL> /

END_ITEM LONGEST_LEAD_TIME

-------------------- -----------------

FRAME 6

HANDLE 5

conclusion

In the end, this exercise reinforced how powerful Oracle’s hierarchical features can be when dealing with real‑world BOM structures. Even when the data model introduces unexpected twists, the combination of START WITH, CONNECT BY, and recursive logic provides a flexible toolkit for navigating parent‑child relationships. With the right approach, even the most tangled hierarchy becomes a predictable and manageable structure.

That said, I am looking forward to someone, anyone who can providing a pure SQL equivalent to my solution.

Cheers, 🎊